Washing with decarbonization: how to do it efficiently

Washing with decarbonization is one of the most important actions in the food area, with impact on health, hygiene and even on the productivity of food production. It refers to the removal of carbonized elements and CO2 that is “stuck” on utensils, tools, trays, and carts subjected to very high temperatures. Find out what this process consists of and why it is so important.

What is decarbonization applied to industrial washing?

Decarbonization in industrial washing is the process of reducing or eliminating grease, carbon, and coal impregnated on the surfaces of utensils and equipment, such as pans, trays, carts, tools, and filters, among many others. The presence of this type of dirt compromises the quality and hygiene of products, promotes bacteria growth and spread, and increases the risk of food contamination.

Decarbonization is only possible through specific techniques and equipment that go beyond routine cleaning and remove the waste from the surfaces effectively and safely. Decarbonization in industrial washing also reduces water and energy consumption since efficient cleaning avoids the need to repeat the process several times. In addition, decarbonization extends the lifespan of equipment and utensils, lessening the need to replace them frequently.

It is important to distinguish decarbonization in industrial washing from decarbonization in an environmental and ecological context. In the first case, it involves the removal of residues encrusted on the surface of utensils and equipment, which are formed during the heating, cooking, or combustion process, with harmful effects on human health. On the other hand, decarbonization associated with sustainability refers to reducing emissions of carbon dioxide and other greenhouse gases. This type of decarbonization combats climate change and involves the transition to renewable energy sources – such as solar, wind, and hydroelectric – and the improvement of energy efficiency.

What are the advantages of washing with decarbonization?

Decarbonization allows food production and distribution areas to become efficient and regularly sanitized workspaces, among other advantages:

- Decarbonization prevents food poisoning from bacterial contamination and pest emergence.

- Kitchen utensils look new and free of chemical residues that inevitably influence the final product for consumption.

- Decarbonization allows companies to save money by not being forced to buy new cookware.

- The removal of carbon and grease shows that daily hygiene is a priority for the establishment.

- Decarbonized equipment and utensils allow professionals to work more efficiently, safely, and confidently.

What utensils can benefit from washing with decarbonization?

Decarbonization in industrial washing can benefit various types of utensils. In general, surfaces exposed to high temperatures are prime candidates for decarbonizing washing. In food operations, iron, aluminum, stainless steel, and Teflon – used in casseroles, trays, and grills – are among the most common.

1. Tray decarbonization system

Trays can accumulate residues in a variety of ways. The most common include fats, sauces, sugars, and other elements that become impregnated on its surface. Decarbonizing prevents the proliferation of bacteria from the waste left on the trays, which, if not removed, can pose a health risk to consumers.

2. Casserole decarbonization system

The decarbonizing system removes residues that are formed on the surface of casseroles and that can be difficult to remove with conventional cleaning. These residues can affect the quality of the food, altering its taste and compromising the safety of consumption. In addition, the decarbonization system extends the life of the casselores and reduces the risk of cross-contamination.

3. Grill decarbonizing system

The most common residues on grills are those that stick to the surface during use. For example, fat that is released from food during cooking can accumulate on the grill, forming a layer that is difficult to remove. This accumulation of residue affects the quality of the food and is also a risk factor for the development of fires.

4. Roasting pan decarbonizing system

Roasting pans are another utensil that can benefit from the decarbonization system. When food is cooked for a long time or at very high temperatures, the surface can burn, leaving dark spots that are difficult to remove. In addition, food residues left on the roasting pan can pose a health risk to consumers.

What are the consequences of not decarbonizing the utensils?

Not decarbonizing utensils can lead to several negative consequences. Some of the main ones include:

- Loss of food quality. Cookware such as grills and roasters build up a thick layer of carbon and grease, and this can affect the quality of the food. Food may not cook evenly and may become tasteless due to the absorption of carbon.

- Fire hazard. The build-up of carbon and fat on utensils can increase the risk of fires. This happens because carbon and grease are highly flammable.

- Bacterial contamination. When utensils are not decarbonized, they accumulate bacteria and other harmful microorganisms that can pose a health risk to consumers. This can lead to outbreaks of foodborne illness and other infections.

- Shortening the life of utensils. Not decarbonizing cookware can shorten its life, prompting early replacement. In other words, it is a waste of resources and money.

Therefore, to avoid these negative consequences, it is important to decarbonize your cookware on a regular basis.

What type of businesses should decarbonize utensils?

Decarbonizing utensils is recommended for any company involved in food preparation, regardless of size or type of kitchen. This includes restaurants, bakeries, pastry shops, hotels, canteens – in schools or hospitals – or catering companies.

Decarbonization is particularly important in industrial kitchens that operate on a large scale, as they tend to accumulate a greater amount of dirt and food residues on utensils. In addition, industrial kitchens generally have tighter deadlines for food preparation and delivery, which means that fast and effective decarbonization of utensils is critical to ensure food safety and the quality of dishes.

Businesses that work with food preparation must follow the hygiene and food safety regulations set by local and national health authorities. This includes regular sanitizing of utensils as part of a quality control and food safety plan. According to the U.S. Public Health Service, kitchen and restaurant equipment should be cleaned and sanitized at least once every 24 hours.

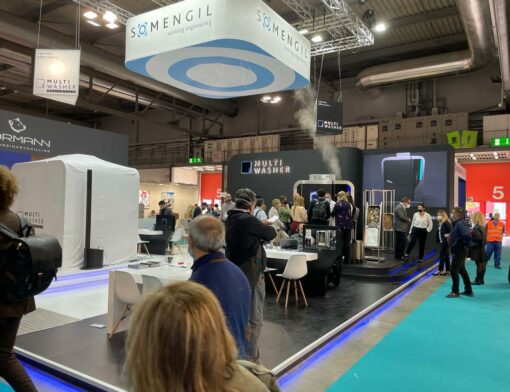

Decarbonizing with the MultiWasher

Decarbonizing is one of the most demanding washing methods because of the rigor and precision it requires. To address this challenge, we developed a high-performance industrial washing machine that ensures total decarbonization of any kitchen utensil – the MultiWasher. This equipment ensures a deep cleaning of any type of utensil, with less water, energy, and detergent consumption than other solutions on the market, in a safe and automatic process. Explore all the advantages in a personalized webinar or contact our team.