Drying methods: which is best for your business?

Industrial drying methods prevent the spread of bacteria and ensure the safety of employees and customers. This is how companies choose the right option.

They’re on surfaces, ceilings and food. In kitchen utensils and cardboard boxes. In medicine trays and supermarket cars. Bacteria are everywhere and everyone can contribute to Hygiene and Food Safety. From the most traditional to the most innovative, there are different industrial drying methods with a single aim: to prevent the spread of diseases that endanger the health of employees, customers and the public.

But which drying methods exist and what are the advantages and disadvantages of each one? This is how to choose one that fits your organization.

What drying methods are there?

There are several industrial drying methods. These are the main ones:

- Convective drying: occurs via direct application of hot air in the drying material

- Contact drying: with this drying method, heat is transferred through a wall or surface (such as towel) to dry the material

- Natural drying: refers to drying through unheated forced air

- Infrared drying: infrared radiationevaporates water and detergents at high temperature

- Freeze drying: submitting materials to freezing temperatures actually dehydrates them. Once rid of water, a combination of pressure and heat restores normal conditions

- Dielectric drying: radiation or radio frequencies transfer heat to materials and dry them the same way a microwave does.

To choose the most suitable drying method for your business, it is necessary to consider which materials to dry, because drying food or medicine, for instance, is not the same thing. But it is also necessary to evaluate the drying process, the production chain, the quality requirements of the final product and the available space.

This is how to land on a drying method that fits your organization.

Which drying methods are most suited to each scenario?

Each of the main drying methods has its own advantages and disadvantages and is most suited to a particular type of need.

Convective drying method

Convective drying, with forced hot air, is a simple, effective and economic drying method for industrial and food products.

However, if not properly controlled, this drying method can dehydrate the surface of the product, forming a heterogeneous result. It can also be a slow process depending on the product and drying temperature.

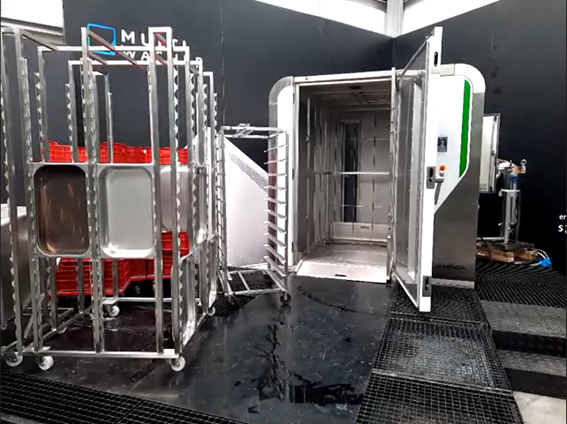

This is the method we chose for MultiWasher, our state-of-the-art industrial washing machine. After years of improvements, we have settled on the best parameters to have total control of drying results. As a result, the MultiWasher can wash and dry anything from boxes to supermarket cars. It is also fast, with results in minutes.

Convective drying is thus one of the most direct ways to improve Food Hygiene and Safety.

Contact drying method

Contact drying is a method that speeds up the natural process. In most industrial applications, it comprises drying a product by contact with heated walls or rotating drums for better homogeneity. But contact drying often means someone has to dry items with towels or cloths manually .

This drying method has several important disadvantages when used on an industrial scale:

- It does not eliminate moisture and storing damp utensils stimulates the development of bacteria;

- It is a manual process that requires allocating resources to a low-value-added task that can easily be automated;

- The equipment used for drying–whether a towel or something else–is fertile ground for the propagation of germs, and it is difficult to control on which surfaces or utensils it will be used next

- Direct contact of the product with hot walls deprives food of its nutrients and does not guarantee the homogeneity of the process.

Natural drying method

Natural drying, by exposure to sun or air, is the oldest solution and prevents the growth of bacteria. It is a drying method suitable for fruits and vegetables.

However, this method has several important disadvantages:

- Requires space to spread the products

- Involves an additional step in the washing process because items must be laid out to dry manually

- Does not preserve all the properties and vitamins of the product

- It is difficult to know exactly how long it takes to dry because the duration depends on weather conditions such as temperature and humidity

- Natural drying immediately after the washing cycle releases steam and chemicals into the internal environment that are harmful if inhaled or deposited on surfaces

At Somengil, we believe it is possible to improve quality control through washing. For this, we designed a drying method in a closed cabin environment in which the main parameters (temperature, speed, amount of water and detergent) are adjusted for each load.

Infrared drying method

Infrared drying evaporates water and detergents at high temperatures. It focuses mostly on the surface of the product, much like a toaster. However, this solution should be avoided for products that do not cope well with exposure to high temperatures.

Freeze-drying method

Lyophilization is the technical term for the freeze-drying method. This is a process in which water is removed from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through a liquid phase. Freeze drying preserves most of the organoleptic properties of food.

However, this technology is relatively slow and expensive. And because it requires a low pressure (vacuum) environment, this drying method is usually used in large production batches, which limit production agility.

Dielectric drying method

Finally, dielectric drying heats the entire volume of a product at the same time. This technology achieves a homogeneous drying and is best suited for the food and medical items to preserve all their properties.

However, dielectric drying makes use of a high energy consumption and is not recommended for many products and materials, including some of the main alternatives to disposable packaging.

When designing an industrial drying method, our priority is the health of the people involved. Improperly drying food, dishes, tools, boxes, trays or other utensils could lead to bacterial growth and endanger the health of workers and customers.

Schedule a webinar or contact our team to learn about our industrial washing solutions.