Food safety: this is what companies can do to improve it

Leading companies in the food industry share a constant concern for food safety. But with ramping infectious diseases, are companies setting the right priorities?

Shortly after his appointment as director of the National Institute of Allergy and Infectious Diseases, Anthony Fauci was called before the US Congress. It was 1984 and Congress expected a presentation on the global widespread of infectious diseases. Mr. Fauci, who would go on to run the US response program to the Coronavirus pandemic, identified a single concern: the HIV virus. It was an unprecedented public health emergency that provided cover for the insidious role played by food safety in the rise of infectious diseases. A link which would remain unnoticed for several years.

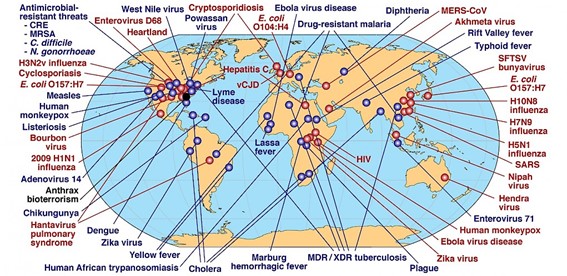

In 2017, a more globalized world faced new diseases and pathogens, such as H1N1 influenza, SARS, West Nile virus, Ebola and Zika. Immunologists rushed to update the map Mr. Fauci had submitted almost 40 years earlier. Experts counseled public and private decision-makers on the need to anticipate, detect and manage new and re-emerging infectious diseases. And several public figures – from Bill Gates to actor Charlie Sheen- warned about the risk of a pandemic of devastating consequences years before it happened.

MAP OF EMERGING AND RE-EMERGING INFECTIOUS DISEASES, 2017

Source: Domestic Preparedness

Despite these important contributions, little had changed until Covid-19. And as the world turned its attention to the fight against Coronavirus, the global number of other infectious diseases continued to spread with deadly speed and silence. But this time, there is a growing awareness about food safety and its impact on public health.

What is food safety?

Food safety is the set of practices implemented in a company with the purpose of preventing food contamination that may affect the health of consumers. For example, inspection, verification, audit and health checks on the entire production chain are tools available for companies to improve food safety.

Food safety is essential in combating the spread of infectious diseases. Restaurants, hotels, hospitals, pharmaceuticals, retailers, food catering and processing companies can implement measures to detect and prevent the spread of food-borne diseases.

What is the impact of inadequate food safety?

The non-implementation of an effective food safety protocol can introduce contaminated products into the food chain. Once those defective items are reported, food companies are subject to interruptions in their operations and to pay for subsequent recalls. On average, a recall operation has a $10 million price tag–and that is just in direct costs.

The long-term effects on consumer confidence are much higher: 21% of consumers report they would not buy from a manufacturer that had to recall one of their food products.

However, the cost of food safety for human life is far greater. Food safety problems are the leading cause of over 200 preventable diseases worldwide. E. coli, Salmonella, Listeria or Norovirus, to name just a few examples, answer for 1.8 million deaths annually. Every year, one in ten people suffers from food-borne illnesses or injuries.

Besides the immediate human cost, food safety affects countries in the developing word disproportionately. The lack of food safety creates a vicious cycle of disease and malnutrition that burdens public health services, disrupts social progress and affects the quality of life.

Bacteria, viruses and infectious diseases: threats to food security

The lack of cleaning, personal hygiene and food preparation routines are some of the major factors that impair food safety and promote the spread of infectious diseases.

Absence of hygiene routines of productive areas

Regular hygiene of production areas, including equipment and utensils, is key to ensuring food safety. To minimize the risk of food-borne diseases, it is necessary to carry out the correct maintenance, wash materials in contact with food at high temperatures and decarbonize utensils regularly.

In addition, it is important to ensure that surfaces are antitoxic, and that there are mechanisms in place to control indoor air conditions, such as temperature and humidity. Companies should take preventive measures to check for bacteria through regular microbiological analyzes.

These are the key drivers behind the lack of food safety.

Lack of food hygiene

Several factors put food safety at risk, such as:

- Purchase of low quality or spoiled ingredients or raw materials;

- Absence of mechanisms for controlling expiry dates;

- Storage of food in inadequate conditions, such as temperature, humidity or PH;

- Preparation of large quantities, beyond what is needed at the time;

- Mixing raw and cooked foods.

Under these conditions, food supplies are potentially harmful to human health. If contamination occurs at any stage, from production to consumption, food safety is compromised.

Lack of personal hygiene

Food workers can make a notable impact on public health. Workers come in direct contact with food should be submitted to regular medical examinations and take special care of personal hygiene and the way they handle food. These practices can prevent food infection during processing, preparation and storage, as well as cross-contamination between raw and prepared foods.

Unsuitable equipment and tools

The lack of equipment, tools and utensils designed for food safety is one of the major difficulties faced by many companies.

These are the most important best practices to follow:

- Choose equipment that ensures a correct and effective disinfection of materials (e.g. dishes), especially if they are in regular contact with food;

- Prefer industrial equipment designed with the workload of each process in mind to meet the highest quality standards;

- Chose materials that are easy to disinfect, resistant to corrosion and nontoxic;

- Organize the workplace to make cleaning easier;

- Minimize the use of detergents in washing and give preference to ecological detergents. Use the detergent quantities recommended by the manufacturers;

- Perform calibration checks of equipment and tools regularly.

Somengil, food security to all the proof

At Somengil, we develop industrial washing machines, so that companies concerned with food safety can easily sanitize any utensil, tool or equipment.

The MultiWasher, a state-of-the-art machine, reaches high temperatures, allowing you to properly sanitize any utensil using minimal amounts of detergent. This way, washing quality is ensured in all cycles.

But perhaps the primary advantage of MultiWasher lies in the ability to do all this with 2/3 less water than any other industrial washing machine.

See the difference in a custom webinar, or get in touch with our team.