Sanitization: what is it and why is it important?

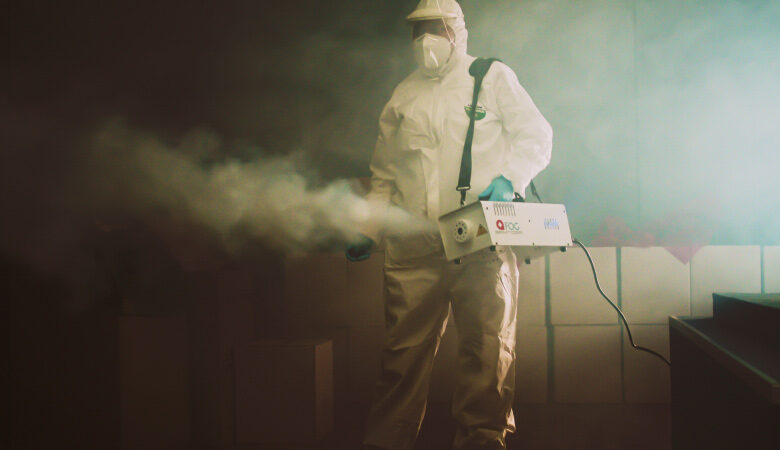

Cleaning is not enough to eliminate harmful microorganisms, especially in places with a large circulation of people and objects. In these cases, only sanitization will do. Find out what it means and how eliminates invisible threats to public health.

What is sanitization and why it matters?

Sanitization relies on special equipment and chemicals to fight viruses and bacteria. Even after intensive cleaning, harmful microorganisms may still be present on surfaces, causing allergies and respiratory diseases such as bronchitis, asthma, rhinitis – or worse.

But sanitization also contributes to better conservation of food, since, without the deterioration caused by bacteria, products gain a longer shelf life. It also has a long-term effect; sometimes, sanitization may remain active for up to six months.

Although sanitization does not guarantee the total elimination of microorganisms, it does reduce the viral load to safe levels without risk of contamination and infection. Therefore, it perfectly complements cleaning. Together, cleaning and sanitization improve the safety and well-being of employees, customers, visitors and suppliers.

How is sanitization different from disinfection?

Both sanitization and disinfection share a common goal of reducing the risk of infection through pathogenic microorganisms, making environments safer. However, these processes differ greatly on the type of products deployed – and its purpose.

Sanitization reduces bacterial load to levels considered safe for human activity by using medium toxicity products. Disinfection, however, ensures a 100% elimination of risk with toxic chemicals. As such, a fruit or vegetable can be ingested after sanitization, but not after disinfection.

Disinfection is thus usually reserved for high-risk environments, such as hospitals and clinics, along with sanitization. To ensure the biosafety in industrial activities and food services without harming the quality of products, sanitization is the most obvious choice.

How to implement sanitization?

Specialized teams should carry sanitization out with high-tech systems, professional products, and protective equipment. Products can vary depending on their toxicity, corrosive effect, concentration, residual effect on food and surfaces to sanitize.

Sanitization produces a protective cover on surfaces, which prevents the proliferation of microorganisms. It usually takes a few hours to take hold, depending on the size of the space to be treated and the environmental constraints. Sites need to be isolated during the sanitisation period but a few hours later it is already possible to return normally to the treated area, without risks to people and animals. Sanitization should be carried out after cleaning the space; otherwise, its effects will be watered down.

Healthcare Sector

In hospitals and clinics, sanitization requires special attention. Patients are natural carriers of viruses and bacteria that can have serious consequences in controlled environments. Sanitization is therefore essential to prevent outbreaks of various types, along with effective disinfection.

Sometimes, costs are easy to quantify. A relatively small outbreak with approximately 40 cases of antibiotic resistance in London, caused by the washing system, cost a single hospital more than €1 million.

MultiWasher Healthtech, a state-of-the-art industrial washing machine developed by Somengil for the hospital sector, does more than just cleaning–it disinfects equipment to ensure it is safe for reuse. It is a closed machine, in cabin format, which meets the requirements of hospital operations. Through a controlled, automated and stable process, it brings benefits to all players in the process: it saves time and achieves consistent results, cycle after wash cycle.

Food Sector

In the food industry, there is a high risk of production contamination, either by the specificities of food products or by the high number of personnel involved. Sanitization is essential to avoid serious repercussions such as intoxication or even death. The financial consequences for the affected companies are also relevant. A recent U.S. study shows that in a restaurant the cost of a single outbreak of a foodborne disease can account for nearly 6 times its annual marketing budget.

The recommended frequency for sanitizing environments varies according to the flow of people. It is advisable to carry out weekly sanitization in high production flows, fortnightly in average flow and monthly in low flows.

At Somengil, we are strongly committed to fight foodborne diseases. Therefore, our machines have the latest industrial washing technology to prevent the spread of microorganisms harmful to public health. With Multiwasher’s high performance, washing takes place in a closed environment to avoid contamination of the workspace, and with a reduced consumption of water and energy. This machine is already working on washing processes in the food industry and responding effectively to bio safety needs.

MultiWasher: prevention and safety first

When you combine technology and innovation with the actual needs of industries, you get groundbreaking results. MultiWasher reflects the health and safety concerns of the various sectors and can sanitize any utensil, tool or equipment – with a high level of automation, intelligent management of temperatures, water, energy and detergent. Schedule a demo or contact our team to see the difference.