Sustainable packaging: 5 steps to make the switch

Sustainable packaging is indispensable for environmentally conscious businesses but also for those looking for practical ways to reduce costs, increase team productivity and create a simply better customer experience. Still, for many companies, making the switch from traditional plastic packaging – with all its implications on the supply chain – can be a challenge. This is what sustainable packaging really means and how to implement it.

What is sustainable packaging and why is it important?

Sustainable packaging is made from recycled raw materials using eco-friendly manufacturing processes. Once used, it can be recycled or discarded with minimal environmental impact.

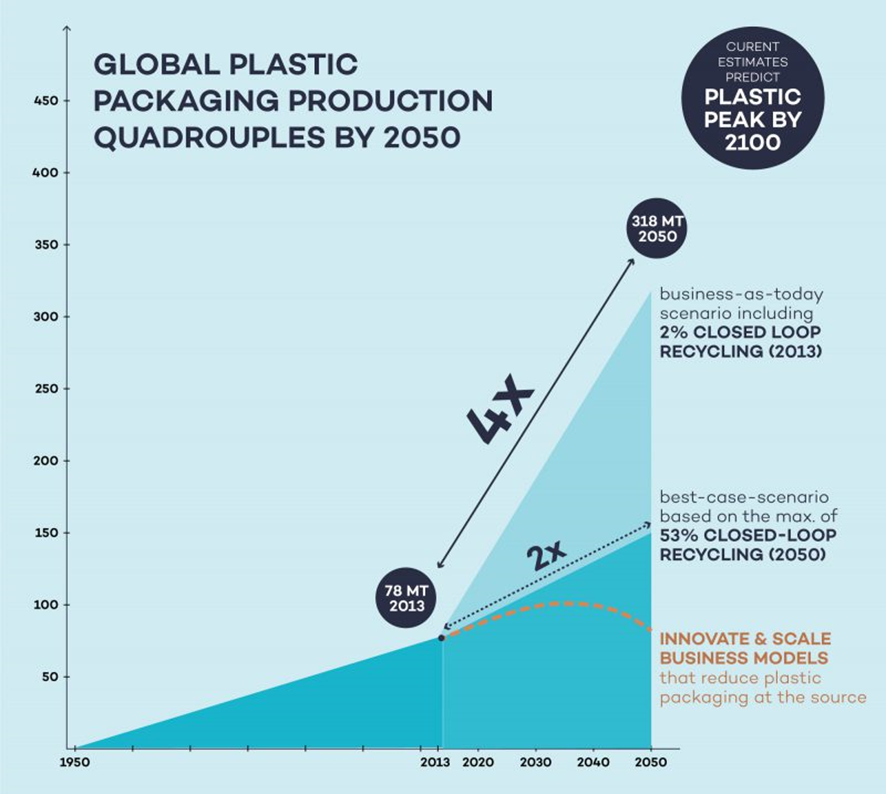

This is an urgent issue and a global priority. But despite much debate and huge media focus, plastic packaging production is on the rise – according to some estimates, it will continue to grow until it peaks in 2100. If nothing changes, by 2050 the world will have quadrupled current production.

Plastic production has been growing for several decades and only the Covid-19 pandemic has slowed this silent trend, albeit slightly. Today, packaging is ubiquitous in our daily lives and virtually every product is packed in protective wrappers that are almost invariably plastic. It is essential that we as a society rethink our consumption habits, and that companies take measures to use sustainable packaging.

Some of the world’s largest consumer brands have already made important steps in this direction. In 2013, L’Oréal started a sustainability program called “Sharing Beauty with All” whose aim is to transform its plastic packaging into 100% recyclable packaging by 2025. Carlsberg also eliminated the plastic rings that involved the packs of beer cans, replacing them with a recyclable glue, thus saving 1,200 tons of plastic per year.

These first experiences have benefits that go beyond environmental protection: they made it possible to reduce logistics costs, streamline the value chain and add value to a brand’s image. Consumers are increasingly informed and aware of the life of materials and are more likely to buy from a company that shares these values. Thus, environmentally responsibility generates trust and is a source of inspiration for consumers.

5 ways to make the switch to sustainable packaging

Making packaging more sustainable can be a challenge for any company. However, there are 5 key steps that every organization can take.

1. Swap plastic for more sustainable materials

Packaging need not be synonymous to plastic. In fact, there are several materials that can replace it, whose impact on the environment is reduced or even null. Take glass, for instance. It is 100% pure and has none of the contamination risks derived from the use of chemicals or additives. Silicone has also been replacing plastic in packaging and kitchen utensils for years, as a safer and more sustainable option.

Other materials, such as stainless steel, bagasse, bamboo and paper have proved promising in the fight against plastic. Thus, reviewing packaging processes and looking for ways to integrate more sustainable materials is an essential step for any company. When giving up plastic entirely is not possible, packaging should at least be 100% recyclable to prevent it from ending up in a landfill or on the seabed.

2. Establish packaging requirements for each product family

Revising the quantity of packaging material for each product family is a simple way to reduce plastic consumption. It may be more practical to have a single packaging size for every product, but adopting standard multiple sizes, according to product volume, is a simple and cost-effective measure.

This will not only cut down on raw materials but also require fewer packaging filling materials and duct tape. To do so, check each product’s family for packaging adjustments. And why not dispense with packaging all together? A study in New Zealand has showed that supermarkets that adopted this trend – known as “nude shopping” – have increased fruit and vegetable sales by over 300%. In short, giving up single-use plastics opens up new possibilities for innovation and to redesign the shopping experience. And there’s no more sustainable packaging than… the one that doesn’t exist.

3. Make packaging creative and reusable

What if we did not discard packaging immediately after its use? Some companies have gone as far as upgrading its containers to serve as dollhouse or animal toys, resulting in a significant lifecycle increase – and plenty of happy customers.

Samsung adopted this measure in the Eco-Package project, repurposing its packaging into useful and decorative pieces, such as a cat tunnel, a bookcase, a magazine holder or a shelf.

Packaging can also have a second life if brands allow consumers to return resistant wrappers and offer incentives to reinforce this behavior. Similarly, a package can be designed to be converted into a reusable shopping bag or a garbage bag. With an effective design, it can even be sought after and shared by the public.

4. Define the right washing method for the packing material

Often, packages are discarded because they are simply dirty to a point that makes recycling impossible. This scenario is frequent in a hospital or other environment with specific disinfection needs. However, effective washing and disinfection could solve this issue and enable reuse.

If you find that in your industry you can reuse packaging after washing, consider the Multiwasher Healthtech, an industrial washing solution that cleans hundreds of types of material. This high performing ware washing machine can be programmed to sanitize every material with just one wash cycle. Recipients come out ready for further use, completely safe.

5. Define a closed loop with suppliers to share packages

Another way to extend the lifecycle of packaging is to implement return routines with suppliers. When you receive goods, you can store packaging and return it in a next supply. Thus, the returned packaging can be used again later, in a closed circuit between your company, its suppliers and even customers.

This change substantially reduces the use of new packaging and is a good example of how the Circular Economy model can be put into practice to fight off the “produce-use-discards” principle. Sharing packaging with suppliers and reusing it reduces waste to a minimum.

MultiWasher, in the front lines of sustainable packaging

Choosing sustainable packaging is one way to take care of the planet – but to be effective, you need a washing solution to match your sustainability strategy. This is the case with the MultiWasher, an industrial washing and disinfection equipment that uses 2/3 less water and 70% less detergent than any other industrial solution on the market. This way, companies that share this strong environmental awareness can sanitize whatever utensil, tool or equipment using minimal amounts of detergent, water and energy. See the difference for yourself in a webinar or contact us to see the MultiWasher in action.