Industrial dishwasher: how to choose

The selection of an industrial disinfection equipment is decisive for the quality of washing, water consumption, detergent and energy of this process. Find out what an industrial washing machine is, what the advantages of these equipment are and how to choose one.

What is an industrial washing machine?

industrial dishwasher is an equipment designed to wash and sanitize utensils of different shapes and sizes, under the health standards established for each sector. Such equipment is designed for companies that, because of their workload and impact on public health, need to wash large quantities of items, safely, efficiently and quickly.

Sectors such as retail, catering, logistics, food, healthcare or pharmaceutical are the primary beneficiaries. In these areas, if the hygiene of utensils is anything less than perfect serious sanitary consequences such as the spread of foodborn diseases may ensue.

What are the advantages of an industrial washing machine

Investing in an industrial washing machine has several benefits, both in terms of efficiency, safety and the environment.

Reduced water consumption

Industrial washing machines represent significant water savings, in proportion to the reduction in charges related to this consumption, besides protecting the planet.

Industrial washing machines can wash a large amount of utensils continuously, avoiding the waste of water that occurs in manual washing processes. In addition, the MultiWasher, a state-of-the-art industrial washing machine developed by Somengil, uses only 7 litres of water per cycle, which saves up to 70% compared with most options on the market.

Less time on repetitive tasks

By washing utensils in large quantity and uninterruptedly, industrial washing machines can reduce the human resources required to wash utensils. Thus, it is possible to move professionals to other activities, improving workflow and increasing overall business efficiency.

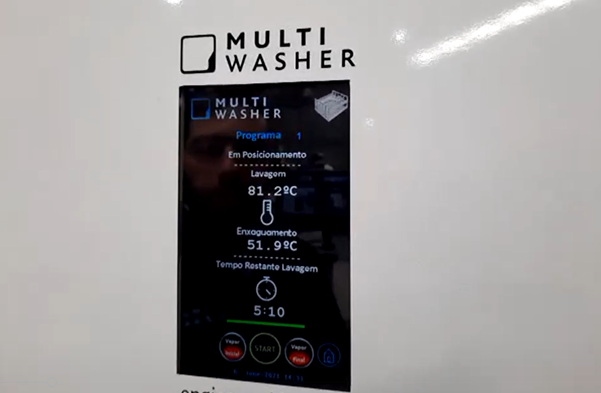

With the MultiWasher, it is possible to customize various washing programmes to the utensils for which they are intended, through an intuitive touch screen. In addition, the MultiWasher eliminates the time spent loading and unloading carts, as staff can insert it directly into the machine and remove them once the washing is over.

Reduced human error

Human action is by nature subject to a degree of error, so manual washing of utensils may not be complete. This risk is not acceptable in areas where thorough hygiene is required, especially in those related to food and health.

That is why industrial washing machines are increasingly indispensable. MultiWasher achieves a consistent result suited for businesses where washing quality and machine performance are critical success factors. It sanitizes any utensil, tool or equipment, with a high level of automation, intelligent management of temperatures, water, energy and detergent.

Decreased detergent and energy consumption

Besides lower water consumption, industrial washing machines use smaller amounts of detergent, drying and even energy. In this way, the washing process ensures that the utensils are not damaged, unlike manual washing, where the risk of falls, scratches or cracks is highest.

To this end, the MultiWasher automatically adjusts the water pressure depending on the utensils to be washed. In addition, it automatically adapts the temperature, and the amount of detergent to the type of product. As a result, the MultiWasher increases the safety and durability of the utensils.

How to choose an industrial washing machine

When choosing an industrial washing machine, it is important to take a few vital criteria into account, as this is an important investment for the productivity and safety of the company.

1. Type of utensils to be washed

Traditional industrial washing machine solutions on the market are usually designed only for a certain type of utensils. Plates or trays? Carts or boxes? This limitation promises the flexibility that industrial washing must offer.

To ensure efficient washing without compromising versatility, at Somengil we have developed the MultiWasher concept. Our industrial washing machine easily adapts to any type of utensil – be it supermarket carts, pans, trays, plates and more. The main washing variables – from water pressure to temperature and cycle duration – are permanently adjusted to the type of utensils in each wash to ensure the expected result.

MultiWasher is widely recognized for its efficiency all over the world, being used in over 30 countries.

2. Wash quality

To measure the quality of the washing it is important to take into account not only the efficiency of the process, but also the degree of cleanliness that results from it.

Using a luminometer, a device that measures the amount of light generated by adenosine triphosphate (ATP), an energy source present in animal, plant, bacterial and fungal cells, it is possible to quantitatively evaluate the result of each washing cycle. The smaller the amount of light generated, the cleaner the utensil will be.

There are reference values [AJ1] for the units of light generated by clean utensils in each industry: in the Food area, it corresponds to a maximum of 500 units of light. A result above this value is indicative of the presence of organisms at too high a concentration. In Health, the requirements are naturally tighter – the disinfection of hospital medical consumables requires a maximum of 100 units of light (except in operating rooms, where it is even more restricted). With MultiWasher, this result is guaranteed in every wash cycle.

In the image below, taken from a custom demonstration for each Somengil customer, an operator tests the results obtained with a magnifying romemeter after a 6-minute washing cycle and consumption of only 7 liters of water. The result? Only 10 units of light, suitable to the highest hygiene standards and much more than required at hospital level. Sign up for a webinar and see the results live.

3. Temperature

A high-temperature industrial washing machine sanitizes heat-based retail utensils. A low temperature machine sanitizes the dishes with disinfectant chemical agents.

Disinfectant agents in a low temperature machine may stain or damage the articles to be washed. Chemicals are needed continuously, which increases the cost per wash and presents itself as an unsustainable and environmentally friendly solution.

Therefore, at Somengil we develop machines that wash at high temperatures in a closed cabin that can reach 85º during the washing process and 90º during rinsing – enough for a great industrial disinfection. The result is a concentration of chemicals of only 2%, a saving of about 70% detergent compared to traditional automatic washing.

4. Ease of use

The washing machine operator plays a key role in saving water, detergent and energy. It is essential that the chosen machine is simple and intuitive to use, not only by experienced employees, but by everyone. For this reason, Somengil washing machines have 20 programmes to choose from, in an easy-to-use touch display.

In these machines, you can associate with each program a type of utensil and the corresponding image. For example, you can allocate program 1 to plastic boxes, program 2 to carts, etc. to make the job easier. Or customize in the most convenient way to your operation. The main washing variables are thus stored to ensure optimized cycles. On the other hand, a set of visual aids allow you to realize the time left to finish the program and the state of the wash at any time.

5. Workflow

The space occupied by the machine is always a factor to take into account. Ergonomic appliances help simplify workflows and reduce the total space required.

At Somengil, our equipment is designed to simplify the operation. Each equipment handles washing, rinsing and drying in a single closed cabin, ideal for the food industry, food service, distribution, logistics and pharmaceutical, with very tight space use requirements.

The MultiWasher is available in 3 standard dimensions, but can be customized for each customer:

- Small: 2,035 × 1,475 x 2,720 meters

- Average: 2,425 × 1,865 × 2,720 meters

- Large: 2,755 × 2,195 × 2,740 meters

Thus, there is no longer a need for a pre-wash and drying area in the work space.

6. Water consumption

A commercial washing machine, with proper installation and maintenance, consumes on average about 23 liters of water during the treatment and cleaning of dishes and utensils. But depending on the model you choose and how you use it, this value can vary greatly.

At Somengil, our machines use only 7 litres of water per cycle, i.e. 70% less than traditional automatic washing. The selection of an efficient and suitable size machine is a key aspect of environmental management best practices.

7. Maintenance

Ease of maintenance is an aspect that influences the longevity of the machine and its energy and water efficiency. At Somengil, we support the customer in the productive use of our equipment, either through its optimized configuration, or through training and training. We also identify unforeseen needs or non-conformities, ensuring the reporting of these situations to the engineering department.

The choice of industrial washing machines for boxes, utensils and containers translates into direct water savings compared to traditional process industrial washing machines. At Somengil, we design our machines respecting the 3 pillars of sustainability (environmental, economic and social) and develop technological solutions that contribute to the optimization of the ecological footprint and the economic efficiency of our equipment, as well as to the well-being of the machine operator.

Multiwasher, high performance industrial washing machine

Industrial washing machines have very significant advantages for any company. Productivity gains, reduced human intervention and improved security make the MultiWasher an appropriate solution for all businesses. Contact our team to see the difference.