Industrial bakery equipment: what is it, why it matters and how to pick one

Industrial bakery machines are an essential piece of equipment for any company looking to increase efficiency, ergonomics and safety, while also improving quality. However, for many managers, choosing the right equipment is not easy. Discover the benefits of these machines, how to choose one, and how to ensure a perfect wash, including the ability to wash with decarbonization.

What are industrial bakery machines?

Industrial bakery machines are professional equipment to complement human action. Like any industrial kitchen equipment, these are large machines, adapted to high production volumes and prepared to receive and work ingredients on a large scale without physical effort of the operator. As such, they speed up the process significantly, with positive repercussions in productivity, ergonomics, and quality.

The most common industrial bakery machines, which are present in the manufacturing processes of virtually every product, are ovens, kneaders, scales, mixers, and coolers. Even traditional models are increasingly productive and smart, equipped with advanced features and automation to optimize planning, preparation, and baking. And these are just some of the advantages of these machines.

What are the advantages of industrial bakery machines?

Industrial bakery machines offer several significant advantages, especially for large scale production environments. These are the main ones.

1. Increased efficiency and productivity

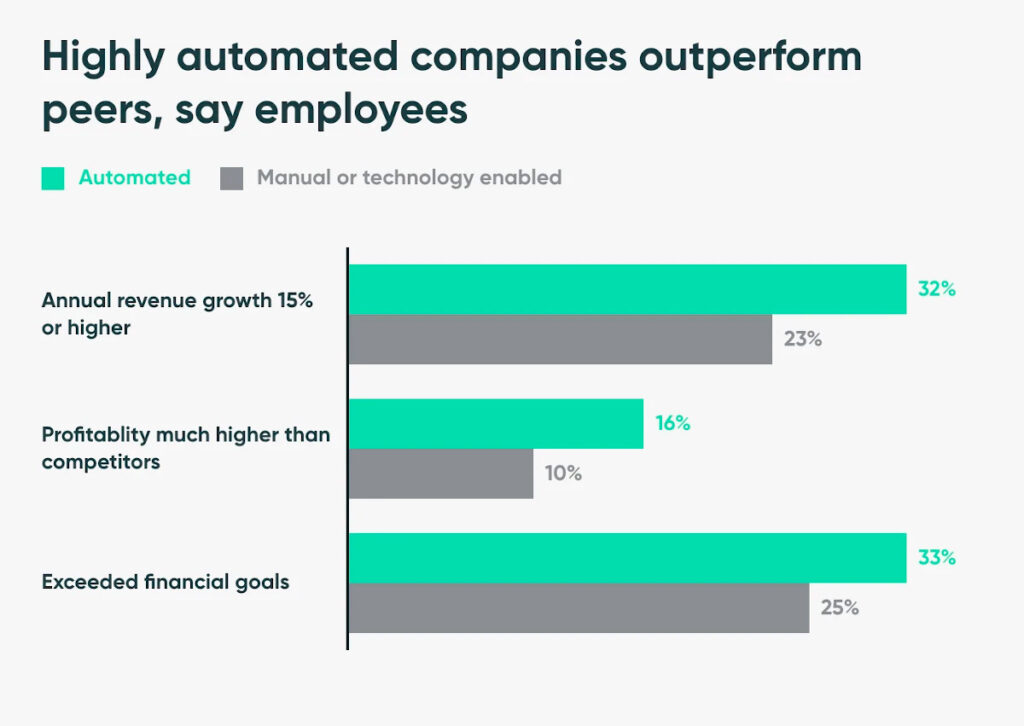

Industrial bakery machines improve efficiency and productivity. They can process large volumes of dough and produce products quickly and consistently. This helps companies respond to shifting demands and speed up the production process, saving time and effort. In fact, “Food Engineering’s” data shows that automation increases productivity by 10 to 15 percent and is a key a success factor in against the competition.

Source: Make

2. Standardization and consistency

Industrial bakery machines deliver a high level of standardization and consistency in production. These machines can perform complex tasks accurately and consistently, ensuring that products have the same quality and taste in every batch. This is especially important for companies that want to maintain their reputation and build customer loyalty.

3. Variety of production options

Industrial bakery machines are versatile and offer a wide range of production options. They can operate with different types of dough. With different accessories and configurations, you can adapt the machines to meet the specific needs of each business.

4. Alocation of human resources for high-impact tasks

By automating production processes, industrial bakery machines can significantly reduce the need for labor. This not only reduces costs but also minimizes human error and increases operational efficiency. Since there is less manual effort involved, the team can focus on other essential tasks. Data from the American Bakers Association and the American Society of Baking indicate that operators in the baking industry are increasingly scarce, so industrial bakery machines are becoming even more essential.

5. Quality control

Industrial bakery machines offer better quality control compared to manual processes. They can guarantee constant temperature and humidity, which significantly cuts production time. Consequently, they increase the profitability of the entire process and reduce variations between batches.

6. Space optimization

Industrial bakery machines are designed to optimize available space. They are usually compact, allowing to maximize production capacity in more limited spaces versus manual operations.

7. Safety and ease of use

Industrial bakery machines have a special focus on user safety. They have their own protection systems, such as safety sensors and emergency stop devices, to prevent accidents. In addition, the machines are intuitive and easy to use, with user-friendly interfaces and simple controls.

Types of industrial bakery machines

Every bakery business has its own specificities, but there are some that are present in the manufacturing processes of almost every product. Find out which ones they are and what you should consider.

1. Industrial ovens

Industrial ovens can reach higher temperatures than their domestic counterparts, in less time and with reduced energy consumption, which gives production more flexibility. Power is one of the most important factors to consider. To calculate what you need, it is important to take into account the production volume that the oven will support. Depending on the recipe and technique, temperatures above 240 °C may be required. It is also important that the oven ensures uniform heat distribution so that all products get the same level of cooking.

2. Kneading machine

As for kneading machines, a dough capacity of between 5 and 25 kg is recommended for medium-sized businesses such as bakeries. For industrial kitchens with constant large-scale production, this equipment should support between 25 and 60 kg – in this case, spiral kneaders are the most suitable.

3. Precision scales

One portion of too much (or too little) water or flour is enough to make a big difference. Therefore, precision scales are another essential piece of equipment for the baking industry. You must have precision scales of at least 1 g, and that can handle your production volume. If, for example, you produce batches of 25 kg of dough, you should choose a scale that can keep up with that amount.

4. Industrial mixers

Although less robust than dough mixers, industrial mixers occupy an important place in baking, especially for working thinner doughs, such as cakes, cookies or puff pastry. Choose the capacity of this equipment according to your production – there are industrial mixers that can handle up to 80 liters of dough.

5. Coolers

Coolers are important to work several different doughs at the same time and in large sizes, since they ensure the right water temperature, in the exact measure. You can find coolers on the market that can hold from 50 to 600 liters of water – even with the possibility of a direct digital connection to the kneading machine. This way you will have total control over the temperature and the amount of water to be added to the dough.

When choosing any industrial bakery machine, it is important to think about the energy consumption of the equipment. In the case of electrical equipment, prefer those with a more economical energy rating: classes A and B are the most efficient, while classes F and G are to be avoided. In addition, consider whether for some specific applications you can use gas or wood-fired equipment. Also in this regard, maintenance deserves a special mention – for example, ventilation blockages can compromise the operating conditions of the equipment, forcing the motors into additional strain that is reflected in the energy bill.

6. Silos

Silos are essential for storing and metering ingredients on a large scale during the production process of bread and other bakery products. They are designed to store dry ingredients such as flour, sugar, salt, and other additives, and have proper sealing systems to keep them fresh and protected from contamination.

7. Dosing

Dosing equipment ensures the precision of the exact amount of ingredients needed for a specific recipe on a large scale. Before being added to the batter, ingredients pass through electronic devices, such as scales or volumetric measurers to ensure consistent and accurate dosing in each production cycle.

8. Conveyors

Conveyors are pieces of equipment integrated into a continuous production line. They move raw dough to different stages of the process, such as cutting, shaping, and fermentation, and can also transport finished products to coolers, packaging stations, and shipping.

9. Laminators

Laminators are important for shaping and leveling dough, especially in the production of products with specific shapes, such as croissants, puff pastry and flaky pastry. They are responsible for laminating the dough into layers with a predetermined thickness, ensuring the evenness of the final product.

10. Other machines

Besides these machines, there are also other equipment essential in an industrial bakery, such as machines that divide the dough into individual portions and shape the products, or machines for controlled fermentation. The integration of these machines optimizes the workflow, ensures efficiency in large-scale production, and maintains the quality of the end products.

How to choose the right bakery equipment

Choosing the right bakery equipment is essential. Here are some important considerations to keep in mind:

1. Type of bakery

Consider the type of products you will be producing – such as bread, cakes, cookies, sweet and savory treats, and more – as specific equipment may be required. Make a list of equipment suitable for your production needs.

2. Production capacity

Assess the quantity of products you intend to produce daily. This will help you to determine the required production capacity of the equipment. Make sure you choose those that can handle the demands of your business, taking into account the production volume and the time required for each process.

3. Available space

Measure the available space in your facility and plan the layout of the equipment accordingly. Consider the size and dimensions of the equipment to ensure that it fits properly and allows for an efficient and safe operation.

4. Quality and durability

Opt for quality bakery equipment made by reliable brands with a good reputation. Durable equipment ensures a longer life span and reduces long-term maintenance and replacement costs. Read ratings and reviews from other users for information on equipment quality.

5. Compliance with safety and hygiene standards

Make sure that the equipment meets the safety and hygiene standards set by regulatory authorities. Check whether they have relevant certifications, such as CE (European Conformity) certification, for example.

6. Ease of use and cleaning

Choose equipment that is easy to operate and clean. Features such as intuitive control panels, clear instructions, and easy access for cleaning are important to ensure efficient operation and proper sanitation of the equipment. The MultiWasher guarantees the perfect washing of any type of industrial bakery machine.

7. After-sales support

Check if the manufacturer or supplier offers after-sales support, such as warranty, technical assistance, and spare parts availability. This is important for solving any problems or for future maintenance.

8. ROI

Set a clear budget for the purchase of the bakery equipment. Consider the initial investment, but also the operating, energy, and maintenance costs over time. Then, calculate estimated sales and estimated ROI.

How to ensure perfect sanitation of industrial bakery machines

One of the major purposes of sanitation in the bakery sector is to safeguard the health of customers and employees. This care must be doubled, considering that it is an industrial environment, with a large amount of equipment and circulation of people. These conditions make this industry a propitious place for the spreading of germs, fungi, and bacteria, and, therefore, with a potential for food contaminations. Therefore, impeccable sanitation must be a priority in the day-to-day operations of this industry. Key guidelines are:

1. Unplug the machine

Make sure to disconnect the machine from the power source before starting any sanitizing procedure.

2. Remove remains and decarbonize

Remove all solid remains such as crumbs, flour, or other food debris from the surfaces and moving parts of the machine. Use suitable brushes or vacuum cleaners to ensure complete removal. When residues are more difficult to remove, decarbonization may be required, which can be provided by the MultiWasher.

3. Disassemble removable parts

If the machine has removable parts – such as beaters, propellers, trays or cylinders – disassemble them according to the manufacturer’s instructions. This will make it easier to clean each component thoroughly.

4. Disinfect the surfaces

Use a disinfectant suitable for the machine surfaces, such as a bleach solution diluted according to the manufacturer’s instructions. Apply the disinfectant to the appropriate areas and leave it on for the recommended amount of time before rinsing again with clean water.

5. Dry thoroughly

Dry all parts and surfaces of the machine thoroughly with clean cloths or let them air dry. This step is important because residual moisture can promote the growth of bacteria or mold. With the MultiWasher, this step is automatically guaranteed, because the machine already integrates the complete drying of the utensils.

6. Reassemble

After complete drying, reassemble the parts of the machine according to the manufacturer’s instructions. Make sure that all parts are properly and steadily installed.

7. Create a cleaning schedule

Establish a regular cleaning and maintenance schedule for industrial bakery machines. This will ensure that they are cleaned regularly and minimize the accumulation of dirt and debris.

8. Provide training

Make sure that the employees responsible for cleaning the industrial bakery machines are properly trained on the correct sanitizing procedures. This includes the correct use of cleaning products, mastering hard-to-reach areas, and raising awareness about the importance of sanitation.

MultiWasher, the machine for washing bakery equipment

In conclusion, cleaning should cover not only the industrial environment, but also the industrial equipment and its accessories used for manufacturing, as boards, beaters, propellers, trays, or cylinders.

The MultiWasher, a next-gen industrial washing machine developed by Somengil, uses the latest technology to ensure complete washing, decarbonization, hygiene and disinfection. It meets every requirement on efficiency, sustainability and safety, and even saves space with its elegant design. It ensures perfect sanitization of all items used in the baking industry, such as industrial mixers, kneaders, measuring utensils, racks, cooling racks, trays, molds, trolleys, and any other industrial auxiliary equipment. Contact us to find out how it works, and see how it will make a difference in the management of your business unit.